Plasma

Description

Plasma cutting is an efficient, fast, and economical method of working stainless steel and nickel alloys. The process relies on a plasma jet, a highly ionized gas at very high temperature, which melts the metal and cleanly cuts it using a stream of compressed air.

This method offers many advantages, including the ability to work with sheets of various thicknesses, from thin sheets to thicker plates up to 6 inches.

Modern plasma cutting, especially in its high-definition versions, ensures clean and sharp edges, reducing the need for finishing steps such as deburring. This makes it an ideal option for producing ready-to-use cut pieces.

All Plasma cut pieces - Plasma cutting Stainless Steel - Plasma cutting Nickel Alloy

Need a quote – Plasma

Whether you're looking for a price quote or information on our range of products and services, JACQUET in the US will get back to you as soon as possible.

| PLASMA | ||||||

|---|---|---|---|---|---|---|

| 156″ x 500″ max size | ||||||

| THK | Standard | |||||

| .1875″ ≤ 1.50″ | +/-.0625″ | |||||

| >1.50″ ≤ 2.00″ | +/-.125″ | |||||

| >2.00″ ≤ 4.00″ | +/-.25″ | |||||

| >4.00″ ≤ 6.00″ | +/-.375″ | |||||

| Bevel | 0°-59° | |||||

| Max Thk. | 4″ | |||||

| Max Width | 120″ | |||||

| Max Length | 480″ | |||||

| Bevel Tolerance | +/- 2° | |||||

Cost

Lower cost than waterjet, laser or saw cutting.

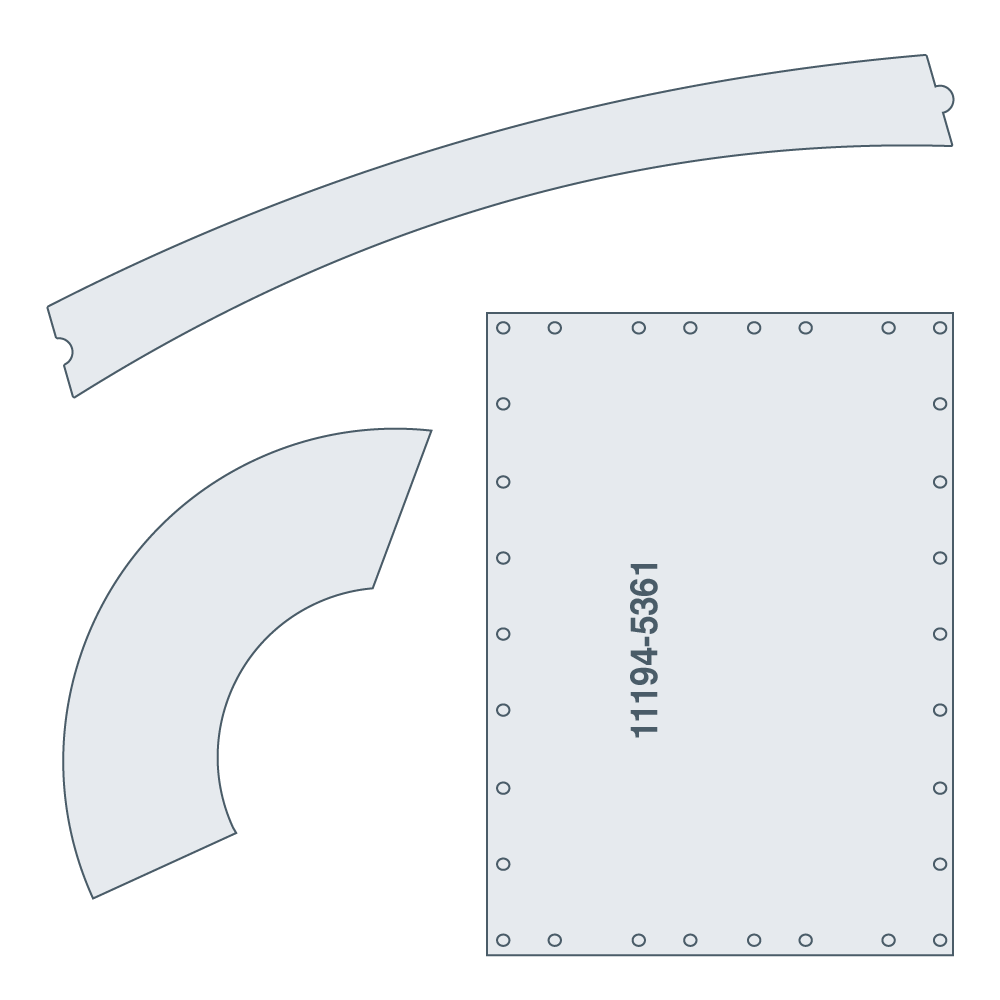

Shapes

Can be used to cut rings, disks and other shapes.

Speed

Quick turn around times and typically shorter lead-times.

Heat Affected Zone

Very high temperatures create a heat affected zone around the cut surfaces. Should be removed by secondary processes.

Cut quality & Tolerances

Small holes and 3D geometry are not available with Plasma cutting. Waterjet and Laser is the alternative.

Heat Sensitive Grades

400 series and PH grades have limitations.