Cutting

JACQUET Finland offers 4 cutting methods:

- Plasma cutting is both an efficient and economical method, perfect for shaping a multitude of stainless steel and nickel alloy parts.

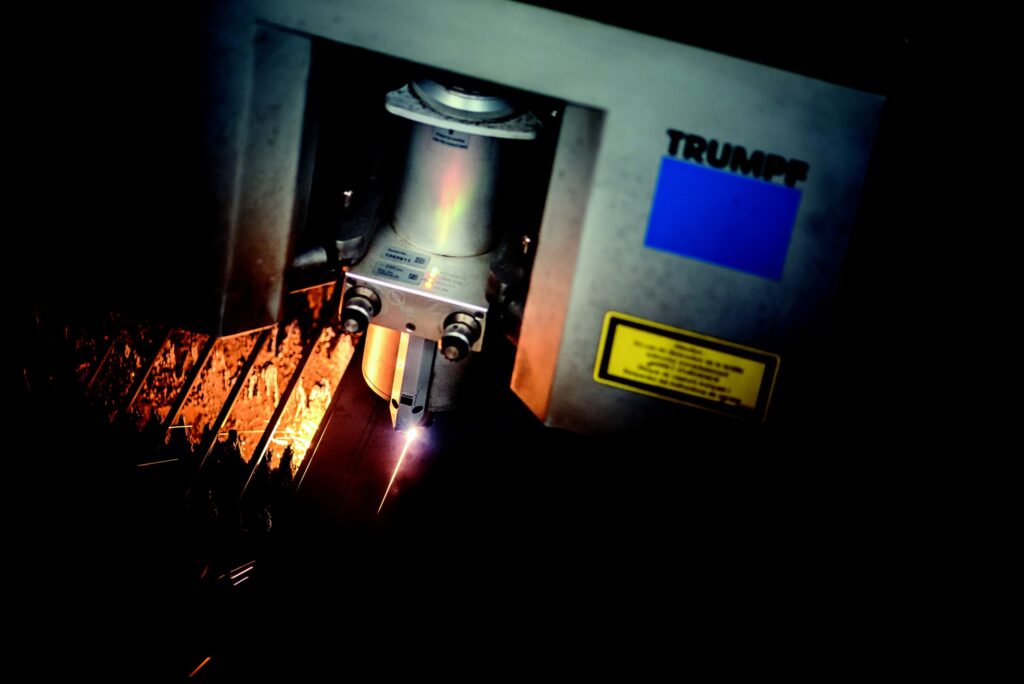

- Laser cutting offers remarkable precision, capable of meeting strict tolerances for materials up to 2 inches thickness. It is particularly suitable solution for mass production of large quantities of parts.

- Waterjet cutting at high pressure stands out for its ability to reduce or eliminate the need for additional processing. It allows the production of parts of all shapes and thicknesses while ensuring cold cutting that preserves the integrity of the material without creating heat-affected zones (HAZ). This technique is ideal for complex cuts in stainless steels and nickel alloys.

- Saw cutting (also known as sawing) is a safe method for obtaining precise perpendicular cuts on medium to thick parts and materials, while avoiding the formation of heat-affected zones (HAZ).