Laser

Description

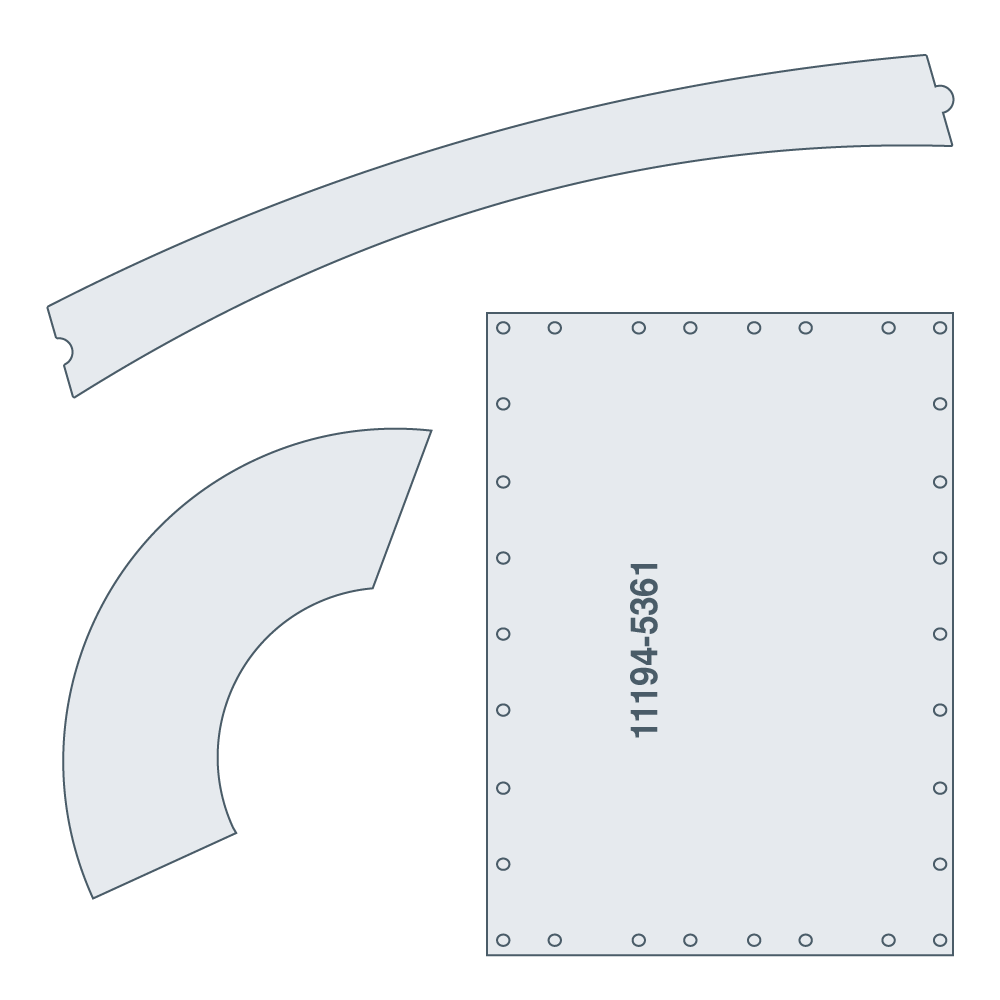

Laser cutting stands out for its high precision, allowing for tight tolerances even with materials up to 2 inches thick. This ability to work with accuracy is essential in applications requiring exact dimensions and high-quality finishes.

This method is particularly well-suited for the production of large series of pieces, where consistent adherence to specifications becomes crucial. Whether dealing with complex or simple shapes, laser cutting offers flexibility that perfectly meets the demands of high-volume projects.

Moreover, laser cutting technology minimizes the risk of material deformation, ensuring the reliability of the produced pieces.

By integrating laser cutting into your production process, you benefit from a high-quality solution to carry out your projects with great responsiveness and unmatched precision.

All Laser cut pieces - Laser cutting Stainless Steel - Laser cutting Nickel Alloy

Need a quote – Laser

Whether you're looking for a price quote or information on our range of products and services, JACQUET in the US will get back to you as soon as possible.

Bystronic – ByStar Fiber

30,000 watts

Cuts up to 2” thick stainless steel

Cuts up to 100″ wide

Cuts up to 244″ long

With positioning speeds of up to 6,681 inches/min and Bilateral positioning repeatability of 0.004 inch, the ByStar Fiber Laser and JACQUET USA can produce your cut pieces with better accuracy and faster delivery than anyone in the industry.

| BYSTRONIC LASER 30KWH | |||

|---|---|---|---|

| 100″ x 240″ max size | |||

| THK | L ≤ 12″ | 12″ < L ≤ 36" | L > 36″ |

| ≤ 0.375″ | ± 0.015″ | ± 0.032″ | ± 0.0625″ |

| > 0.375″ ≤ 0.75″ | ± 0.023″ | ± 0.040″ | ± 0.072″ |

| > 0.75″ ≤ 1.125″ | ± 0.043″ | ± 0.060″ | ± 0.092″ |

| 1.25″ ≤ 2″ | ± 0.0625″ | ± 0.0625″ | ± 0.0625″ |

Steel laser cutting, as an advanced manufacturing technique, brings multiple benefits to the table. From precision and speed to quality and efficiency, the laser cutting advantages are manifold. Below, we detail these benefits:

High Precision

Steel laser cutting operates with extremely high precision, down to the smallest measurements. Creation of intricate designs, patterns, and shapes that might be challenging with traditional cutting techniques.

Versatility

Laser cutting shines in its ability to handle a wide variety of shapes and sizes, regardless of the complexity. Cutting thick steel plates or thin steel sheets.

Speed

Compared to other metal cutting methods, laser cutting significantly improves the speed of operation.

Quality

Laser cutting creates clean, smooth, and high-quality cut edges. Reduces the need for further finishing processes, saving time and resources.