Waterjet

Description

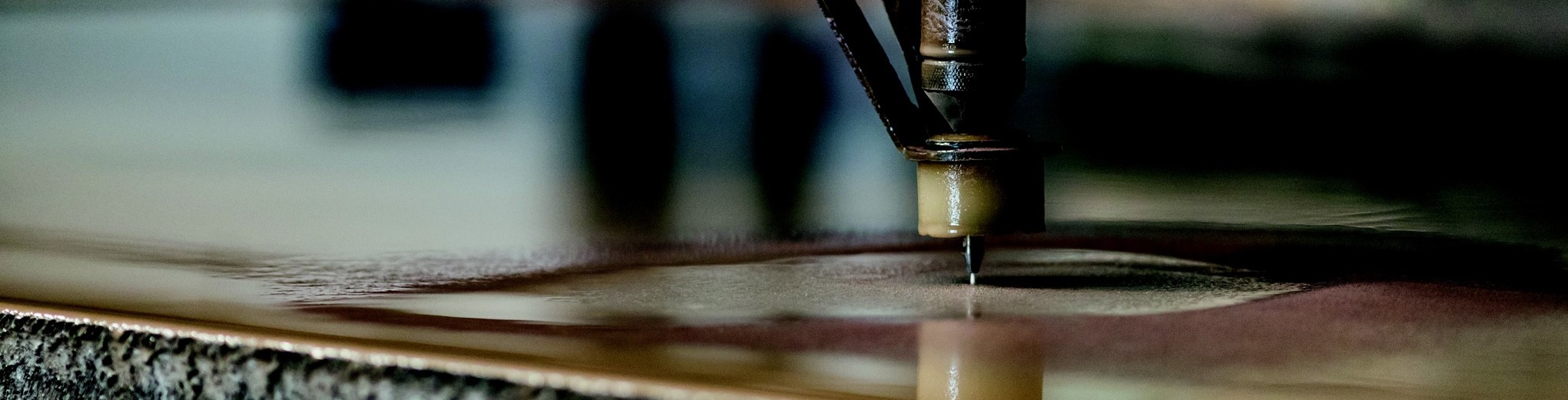

Waterjet cutting is a highly precise and versatile solution for working with stainless steel and nickel alloys. Using a very high-pressure water jet, this method cuts materials without generating heat, eliminating the risk of thermal deformation or changes to the metal's mechanical properties.

This process is particularly suited for parts requiring extreme precision, especially in demanding industrial applications. It can cut sheets and plates of various thicknesses, up to 6 inches, while maintaining tight tolerances. The resulting cut edges of cut pieces are clean and free of significant burrs, reducing the need for additional finishing.

Waterjet cutting is ideal for projects where material quality must be preserved, such as in the aerospace, chemical, or energy sectors. It enables the production of complex parts, detailed contours, and specific shapes, while fully maintaining the properties of nickel alloys and stainless steel, including their resistance to corrosion, heat, and wear.

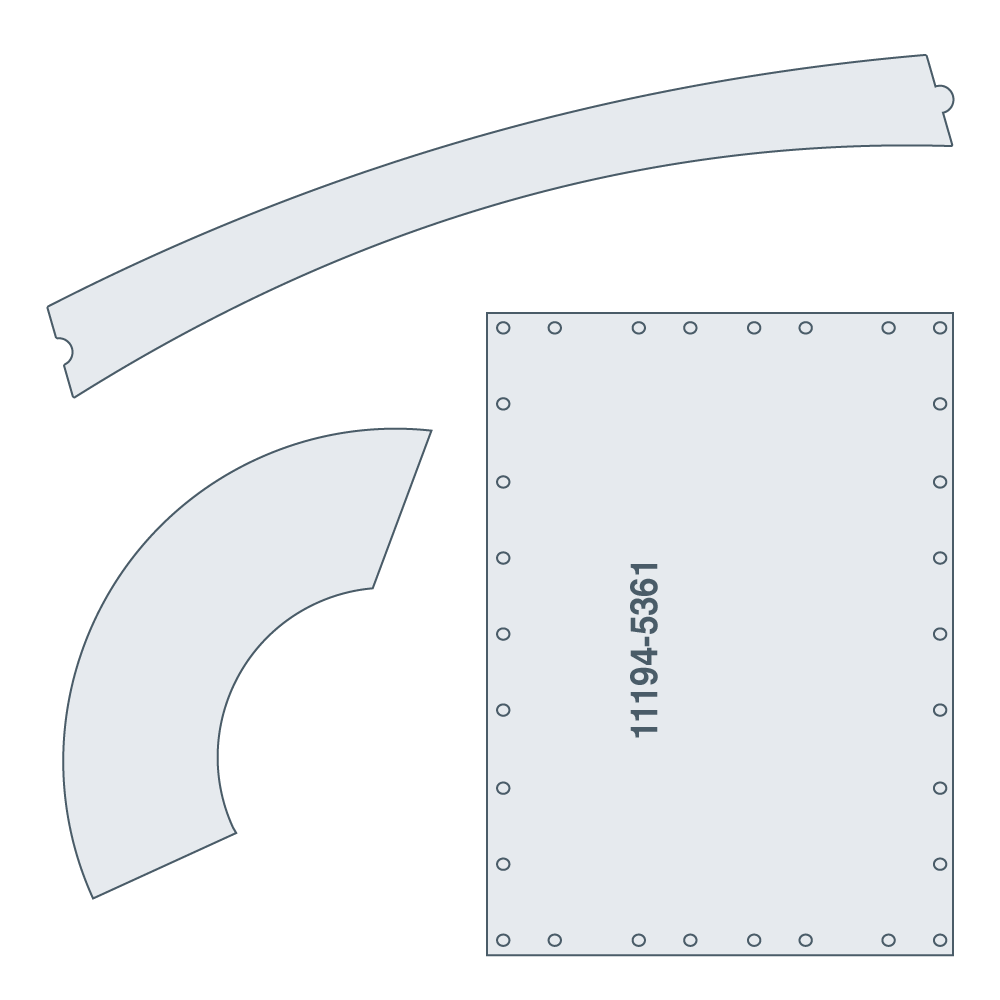

All Waterjet cut pieces - Waterjet cutting Stainless Steel - Waterjet cutting Nickel Alloy

Need a quote – Waterjet

Whether you're looking for a price quote or information on our range of products and services, JACQUET in the US will get back to you as soon as possible.

| WATERJET | |||

|---|---|---|---|

| 120″ x 315″ max size | |||

| THK | Standard | Premium | Best |

| .1875″ ≤ 2.50″ | +/- .0625″ | +/- .03125″ | +.032″/-0″ |

| >2.50″ ≤ 4.00″ | +/- .125″ | +/- .0625″ | +/- .03125″ |

| >4.00″ ≤ 6.00″ | +/- .1875″ | +/- .0625″ | +.0625″/-0″ |

| No common cuts on bevel head | |||

| Bevel | 0°-59° | ||

| Max Thk. | 4″ | ||

| Max Width | 96″ | ||

| Max Length | 300″ | ||

| Bevel Tolerance | +/- 1° | ||

No Heat-Affected Zone (HAZ)

Unlike many other cutting processes, waterjet cutting is a cold-cutting technology, meaning it does not generate heat during the cutting process. This lack of heat helps prevent material distortion, warping, or changes in the material properties.

Quality of Cut

Can reduce or eliminate secondary machining operations saving time and money.

Waterjet cuts can have various levels of quality. Depending on your needs we can cut using a Q3, Q4, or Q5 cutting standards to match your specific requirements.

Our standard is a Q3 which optimizes quality with price. This is the default choice for the majority of our customer base. Q4 and Q5 cuts are higher quality cuts but the higher quality and a much slower cut comes at a higher cost.

Complex operations potential

JACQUET in the US waterjet systems can include 5-axis and dual-heads to reduce cutting times and get closer to a finished part. With a 5-axis system, we are able to cut complex operations like beveling, contouring, and flight paths. These capabilities will get you closer to a finished machined part saving CNC machine time.